MENUProduct center

BacktrackYour location:Home → Producs → Grinding and polishing robot

Description

Polishing robot work video

一. Application range of Songle polishing robot

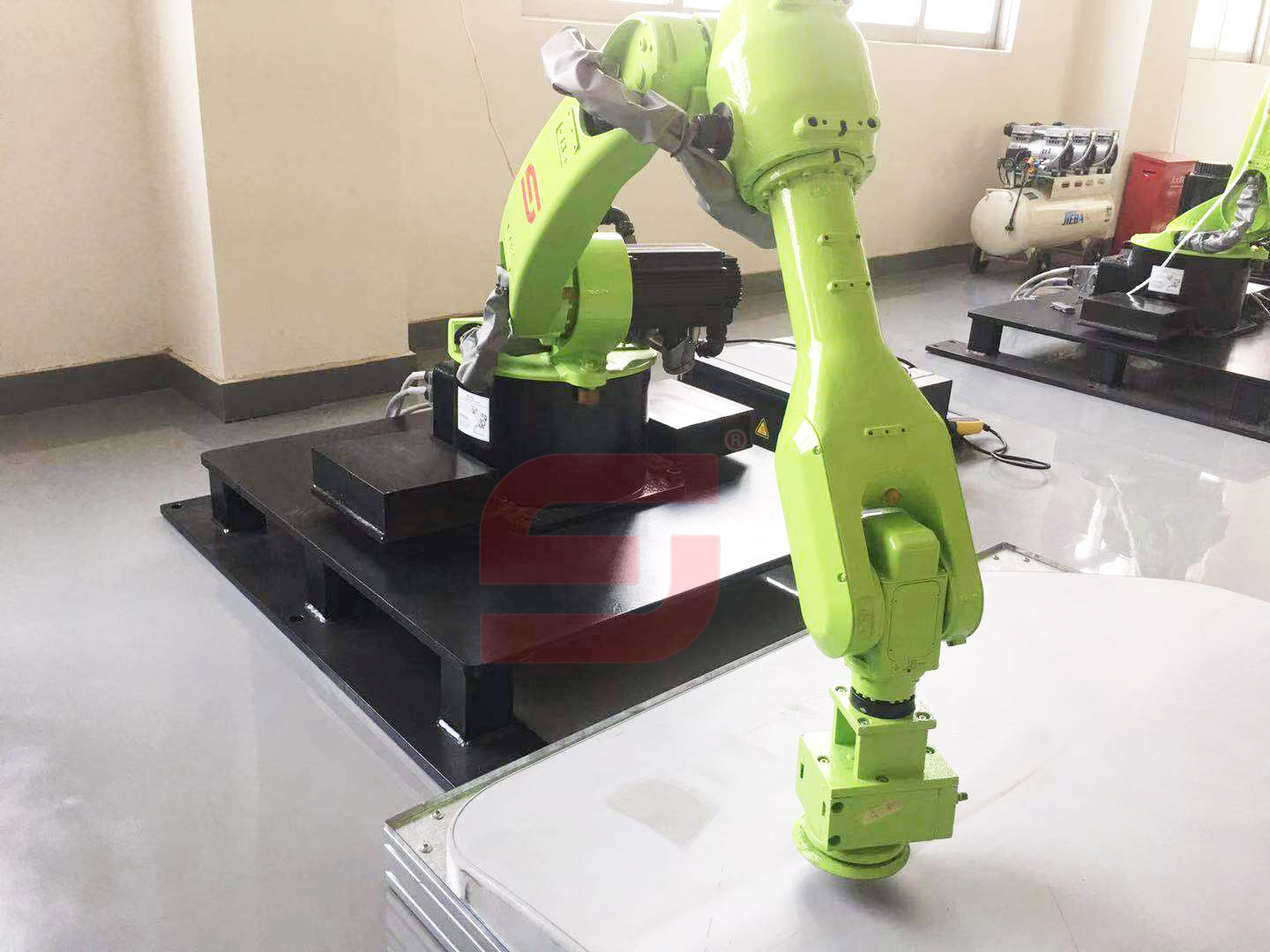

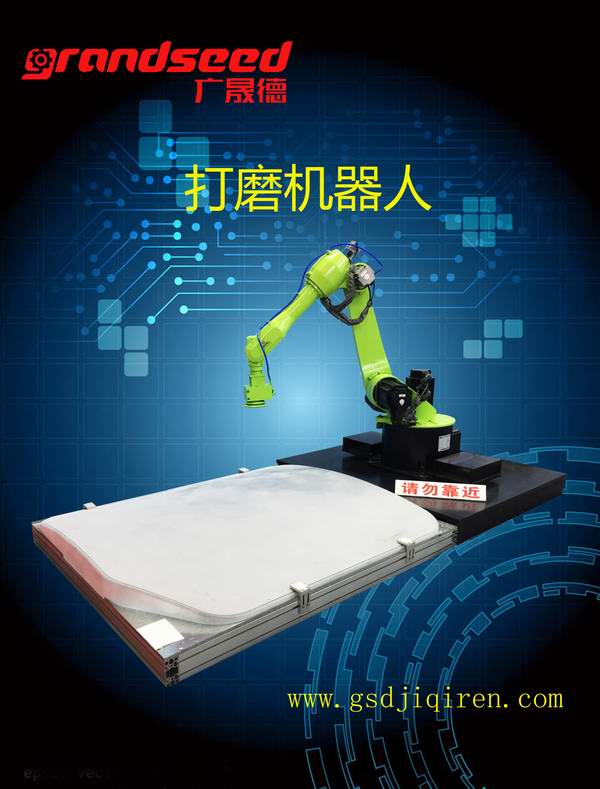

The polishing robot developed by the professional team of Shenzhen Songle Robot Co., Ltd. is mainly used for the surface polishing treatment of hardware products. It is widely used in sanitary ware, automobile, motorcycle parts, door locks, die casting industry, precision casting industry, gravity casting industry, faucet industry, The polishing processing of pendants and other industries is a kind of artificial intelligence operation equipment, directly importing the product 3D drawing of the drawing software (multiple CAM software), and the Logen Studio robot polishing software package processing, directly generating executable files, and then automating the workpiece Check polishing.

The categories of polishing robots developed by Songle Robotics have the following ranges

1. Bathroom polishing robot. Faucet polishing robot, bathroom pendant polishing robot, shower polishing robot, two-way/three-way/four-way polishing robot, zinc alloy faucet polishing robot, copper alloy faucet polishing robot, stainless steel faucet polishing robot.

2. Kitchenware hardware polishing robot. Pot handle polishing robot, pot ear polishing robot, pot polishing robot, pot lid polishing robot.

3. Construction hardware polishing robot. Door lock polishing robot, door handle polishing robot, door hinge polishing robot, zinc alloy polishing robot, stainless steel polishing robot.

耀彩网4. Sports equipment hardware polishing robot. Golf head polishing robot, treadmill hardware polishing robot.

5. Medical hardware polishing robot. Stainless steel bone polishing robot, other medical equipment polishing robot, wheelchair hardware polishing robot.

耀彩网6. Furniture hardware polishing robot. Five-star chair foot polishing robot, furniture hardware polishing robot.

7. Auto parts polishing robot. Auto wheel deburring and polishing robot, aluminum alloy wheel deburring and polishing robot, stainless steel wheel deburring and polishing robot, car guard bar polishing robot, car door handle polishing robot, car hardware polishing robot.

8. Polishing robots for mobile phones and IT industries. Iphone shell polishing robot, laptop shell polishing robot.

二. Application advantages of Songle polishing robot

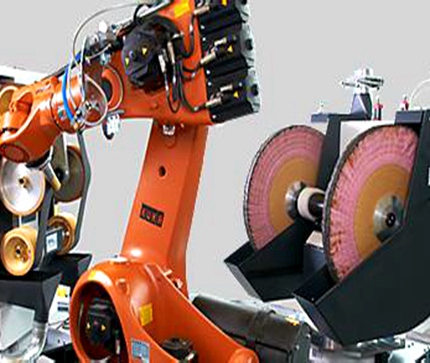

耀彩网The robot automatic polishing system is fully automatic controlled by an industrial robot, can be edited repeatedly, and can complete various polishing operations in a three-dimensional space. The robot hand grips the vehicle with a load-bearing capacity of 50-80KG, and the arm length is 1900-2150mm. The polishing machine has multiple available grinding contact wheels. During the grinding process, the robot can control the speed of the abrasive belt, automatically adjust the tension of the abrasive belt, and automatically select the currently available contact wheel.

耀彩网The robot polishing machine has an automatic position compensation function. During the grinding process, it can automatically detect the wear of the polishing wheel and automatically adjust the position of the polishing wheel to compensate for the position error caused by the wear of the polishing wheel. The polishing machine has a belt break alarm function, which effectively eliminates the danger and time waste caused by the idle operation of the robot after the belt breaks. The new robot flexible polishing system combines a force-compensated polishing machine with robots, sensors, and controllers to form an intelligent manufacturing system. Compared with ordinary mechanical polishing and manual polishing, it can guarantee the surface quality of the processed workpiece when polishing complex curved surface workpieces. The processed products have a high degree of quality consistency and the processing efficiency is greatly improved.

耀彩网The entire polishing robot is sealed in the machine room, and the waste pollution generated during the polishing process can be effectively cleaned and controlled without polluting the environment or affecting the health of the operators. The robotic polishing system has irreplaceable advantages in the field of finishing of complex-shaped workpieces.

Shenzhen Songle polishing robot is fully automatic controlled by an industrial robot, can be edited repeatedly, and can complete various polishing operations in a three-dimensional space.

耀彩网The robot hand grips the vehicle with a load-bearing capacity of 50-80KG, and the arm length is 1900-2150mm.

The Songle polishing robot has multiple available grinding contact wheels. During the grinding process, the robot can control the speed of the abrasive belt, automatically adjust the tension of the abrasive belt, and automatically select the currently available contact wheel.

Songle polishing robot has an automatic position compensation function. During the grinding process, it can automatically detect the wear of the polishing wheel and automatically adjust the position of the polishing wheel to compensate for the position error caused by the wear of the polishing wheel.

The Songle polishing robot has an alarm function for belt breakage, which effectively eliminates the danger and time waste caused by the robot idling after the belt breaks.

Provide automatic polishing offline programming software, so that you can truly complete the polishing process in the office, greatly reducing your programming time.

We have professional polishing process programmers who provide real technical support to help you solve difficult polishing tasks and reduce production time.

耀彩网The professional robot fixture design team adopts more professional fixture design to greatly improve the polishing effect.

三. Polishing characteristics of Songle polishing robot

耀彩网Consistency: Polishing is a tedious and repetitive work, and the robot can work continuously and stably

耀彩网Improve quality: the robot can work continuously without fatigue, which is very suitable for the needs of this work

Employee safety: related operations have potential safety hazards, and robots reduce the safety risks of the factory

Environmentally friendly: The dust environment at the polishing job site is extremely harsh, and the robot can work safely in the smoke and dust environment

耀彩网Reduce waste: The automated robotic polishing system can easily provide the consistency and accuracy needed to ensure that the product is uniform and thoroughly polished.

Reduce cycle time: The polishing robot is programmed to apply the right amount of pressure and just moves in the right direction, resulting in faster and more effective performance than manual applications.

The robotic polishing system can be widely used in the polishing operations of complex curved surfaces, such as aviation blades, steam turbine blades, water turbine blades, windmill blades, titanium alloy artificial joints, sanitary ware, digital home appliances, stationery and sports goods and other final processing processes, so that the surface quality of the workpiece can be obtained. A substantial increase.

4000-599-111

4000-599-111